February 1, 2023

Plastic film production involves several steps, including polymer selection, extrusion, stretching, and cutting. In the first step, polymer pellets are melted and formed into a thin sheet using an extruder. This sheet is then stretched in both directions to produce a uniform, oriented film. Finally, the film is cut into the desired size and shape.

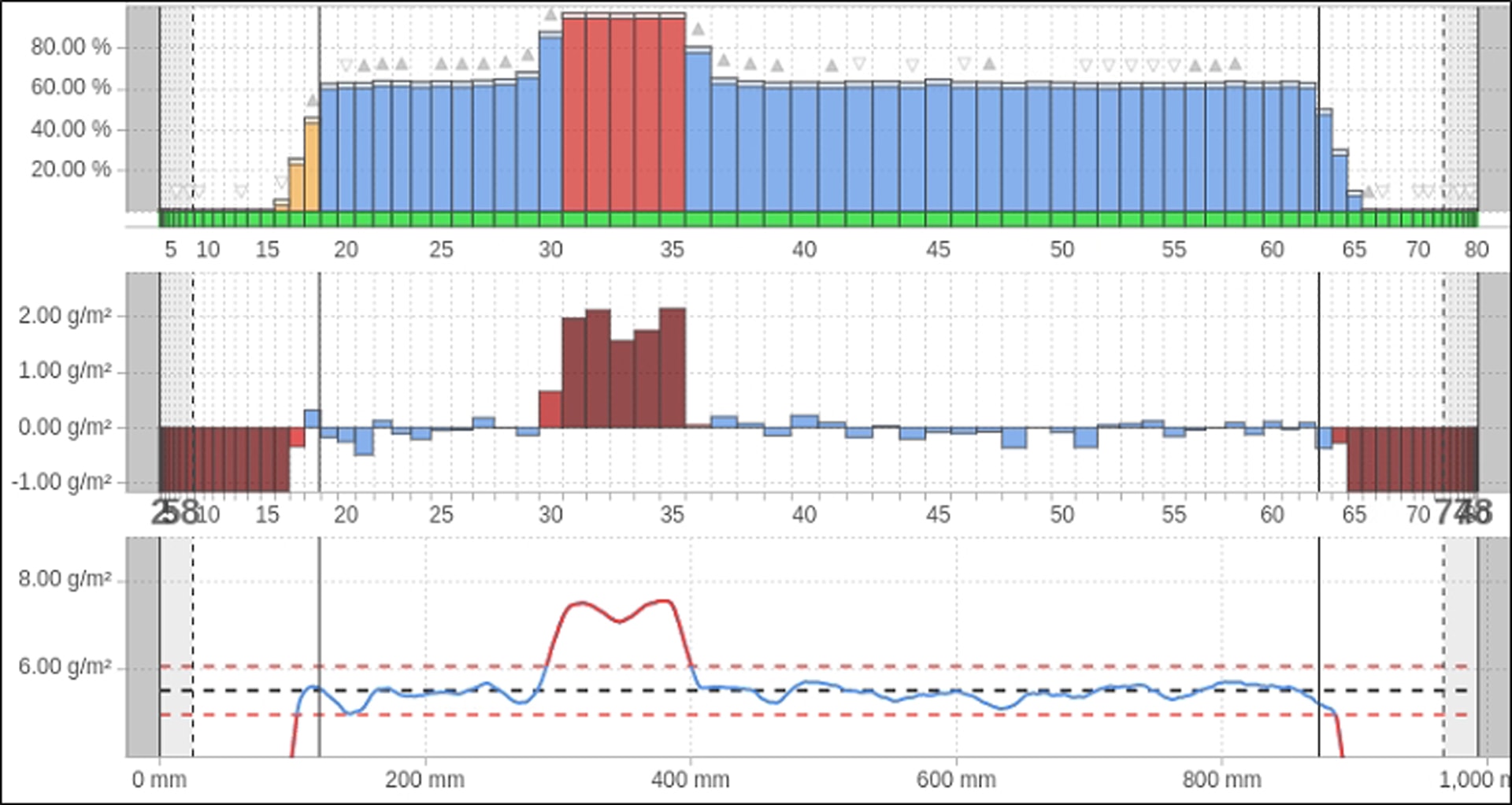

Thickness measurement during the manufacturing process is crucial to ensure quality control and to meet specific industry requirements, especially in the field of batteries and phone screens. These products have strict specifications regarding the thickness of the plastic film used, as the thickness can directly impact the durability and functionality of the final product.

Accurate thickness measurement helps manufacturers monitor and control the production process, ensuring that the plastic film produced is within the desired specifications. If the thickness deviates from the specifications, adjustments can be made to the production process to correct it.

In conclusion, the production of plastic films involves several steps and thickness measurement plays an important role in ensuring quality control. Accurate thickness measurement is especially important in industries such as batteries and phone screens, where the specifications for plastic film thickness are strict and can impact the final product’s durability and functionality.

In conclusion, the production of plastic films involves several steps and thickness measurement plays an important role in ensuring quality control.

“

Discover our measurement solutions for the EXTRUSION manufacturing process.

Related Articles

Enhancing Aseptic Package Production

Optimize aseptic package production with Scantech’s advanced measurement solutions. Improve quality, productivity, and safety.

How to Calculate Density: Formulas, Examples, and Practical Tips

Density is a fundamental concept encountered in numerous fields of science and engineering, ranging from materials science.

Online Non-Contact Measurement: The Ideal Solution for Precise and Contact-Free Measurements

In a world where efficiency and precision are essential, Online Non-Contact Measurement has become a must-have solution for many industries.