February 21, 2023

The BIAX process, also known as biaxial stretching, is a method of manufacturing battery separator films that is used to improve the performance and safety of batteries. The process involves stretching the film in two directions, or axes, to create a highly oriented and uniform film. This results in a thinner, stronger, and more flexible film that is well suited for use as a separator in lithium-ion batteries.

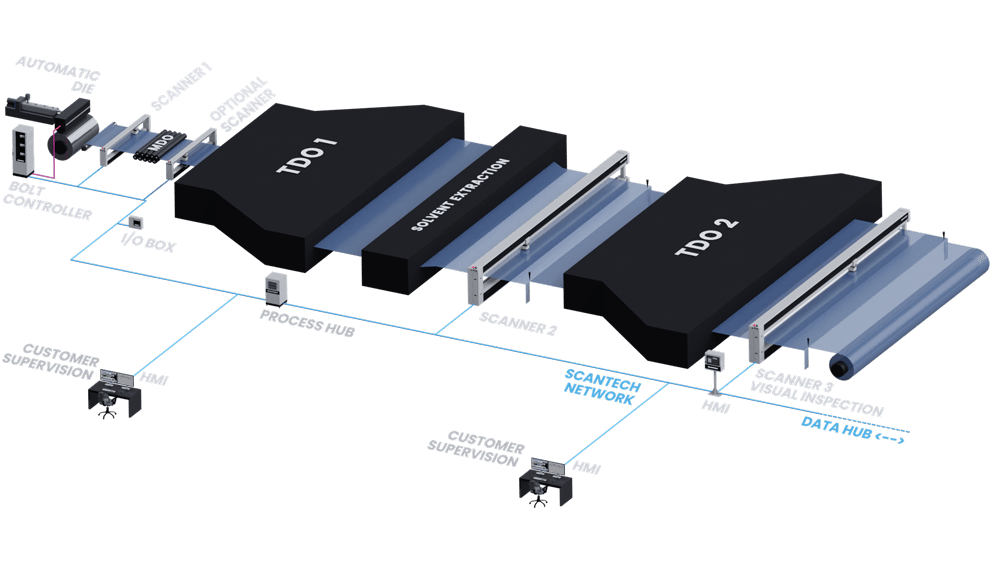

- Extrusion: The first step in the BIAX process is the extrusion of a polymer melt. The polymer is extruded through a die to form a flat film. The properties of the film can be adjusted by changing the composition of the polymer, the temperature of the extrusion, and the speed of the extrusion.

- Orientation: After extrusion, the film is stretched, or oriented, in the machine direction. This step helps to align the polymer molecules in the film and create a stronger and more uniform film.

- Biaxial Orientation: The final step in the BIAX process is the stretching of the film in the transverse direction. This step is critical for creating a highly oriented and uniform film. The film is stretched in both the machine and transverse direction by using heat and tension, and the final film thickness is reduced.

- Calendaring or Roll-up : The stretched film is cooled, and then it is passed through a series of rolls, with different surface roughness, to improve the final film properties, like thickness and smoothness. The film is then wound onto a roll for further processing or packaging.

- Inspection : The final film is inspected for any defects, and measurements such as thickness, width and porosity are made. The film can then be cut to the desired size and shape for use in battery applications.

In conclusion, the BIAX process is a key method of manufacturing battery separator films, it involves the extrusion, orientation and biaxial orientation of a polymer.

The BIAX process is a key method of manufacturing battery separator films

“

Discover our measurement solutions for the BIAX manufacturing process.

Related Articles

Enhancing Aseptic Package Production

Optimize aseptic package production with Scantech’s advanced measurement solutions. Improve quality, productivity, and safety.

How to Calculate Density: Formulas, Examples, and Practical Tips

Density is a fundamental concept encountered in numerous fields of science and engineering, ranging from materials science.

Online Non-Contact Measurement: The Ideal Solution for Precise and Contact-Free Measurements

In a world where efficiency and precision are essential, Online Non-Contact Measurement has become a must-have solution for many industries.