February 23, 2023

A Guide to Weight Measurement Gauges in the Metal Industry

Introduction:

Weight measurement gauges are an essential part of the metal industry. They are used to measure the weight of raw materials, finished products, and scrap metal. Accurate weight measurements are critical for ensuring quality control, complying with regulations, and optimizing production processes. This article will provide an overview of weight measurement gauges used in the metal industry, including their types, applications, and benefits.

Types of Weight Measurement Gauges: There are several types of weight measurement gauges used in the metal industry. The most common types include:

- Load Cells: Load cells are sensors that measure the weight of an object by converting the mechanical force into an electrical signal. They are commonly used in industrial scales and weighbridges.

- Weighing Indicators: Weighing indicators are electronic devices that display the weight measured by load cells. They can be used in conjunction with various types of scales, including platform scales, bench scales, and floor scales.

- Crane Scales: Crane scales are used to measure the weight of large or bulky objects that cannot be weighed on a conventional scale. They are attached to cranes and hoists and can measure weights ranging from a few kilograms to several tonnes.

Applications of Weight Measurement Gauges: Weight measurement gauges have a wide range of applications in the metal industry. Some of the most common applications include:

- Inventory Control: Weight measurement gauges are used to measure the weight of raw materials, finished products, and scrap metal. This information is used to keep track of inventory levels, monitor production processes, and optimize material usage.

- Quality Control: Accurate weight measurements are essential for ensuring that products meet quality standards. Weight measurement gauges can be used to verify the weight of finished products and to detect any variations or defects.

- Compliance: Many industries have regulations and standards that require accurate weight measurements. Weight measurement gauges can help companies comply with these regulations and avoid costly penalties.

Benefits of Weight Measurement Gauges: The use of weight measurement gauges in the metal industry offers several benefits, including:

- Improved Accuracy: Weight measurement gauges provide accurate weight measurements that can help companies optimize production processes, reduce waste, and improve product quality.

- Cost Savings: Accurate weight measurements can help companies reduce costs by minimizing material waste and avoiding penalties for non-compliance with regulations.

- Increased Efficiency: Weight measurement gauges can help companies improve efficiency by providing real-time data on weight measurements, enabling faster decision-making and process optimization.

Conclusion:

Weight measurement gauges are an essential part of the metal industry. They provide accurate weight measurements that help companies optimize production processes, comply with regulations, and improve product quality.

Weight measurement gauges are used to measure the weight of raw materials, finished products, and scrap metal.

“

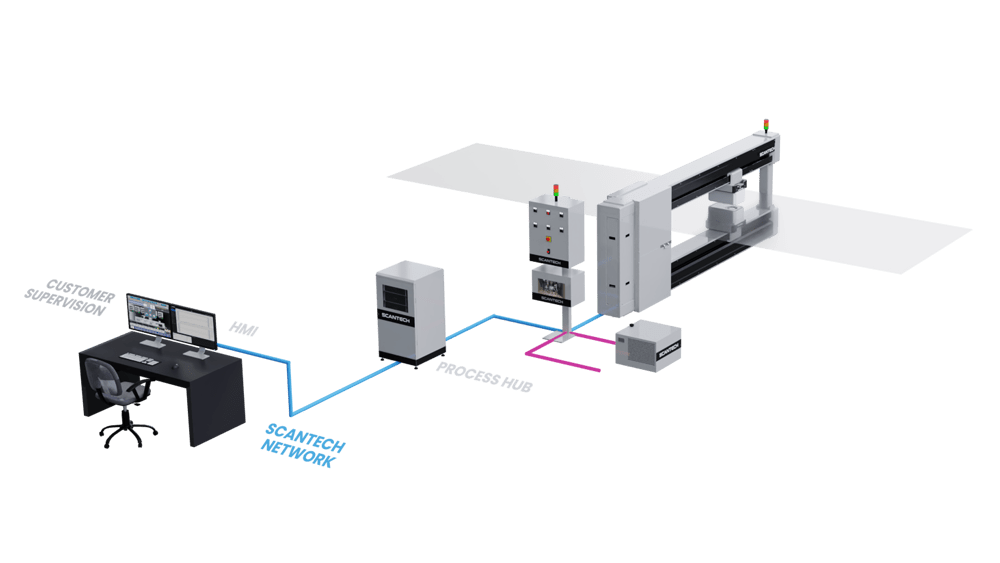

Discover our measurement solutions for the Weight measurement.

Related Articles

Enhancing Aseptic Package Production

Optimize aseptic package production with Scantech’s advanced measurement solutions. Improve quality, productivity, and safety.

How to Calculate Density: Formulas, Examples, and Practical Tips

Density is a fundamental concept encountered in numerous fields of science and engineering, ranging from materials science.

Online Non-Contact Measurement: The Ideal Solution for Precise and Contact-Free Measurements

In a world where efficiency and precision are essential, Online Non-Contact Measurement has become a must-have solution for many industries.