BLOWN FILM

MEASUREMENT SYSTEM FOR

BLOWN FILM LINES

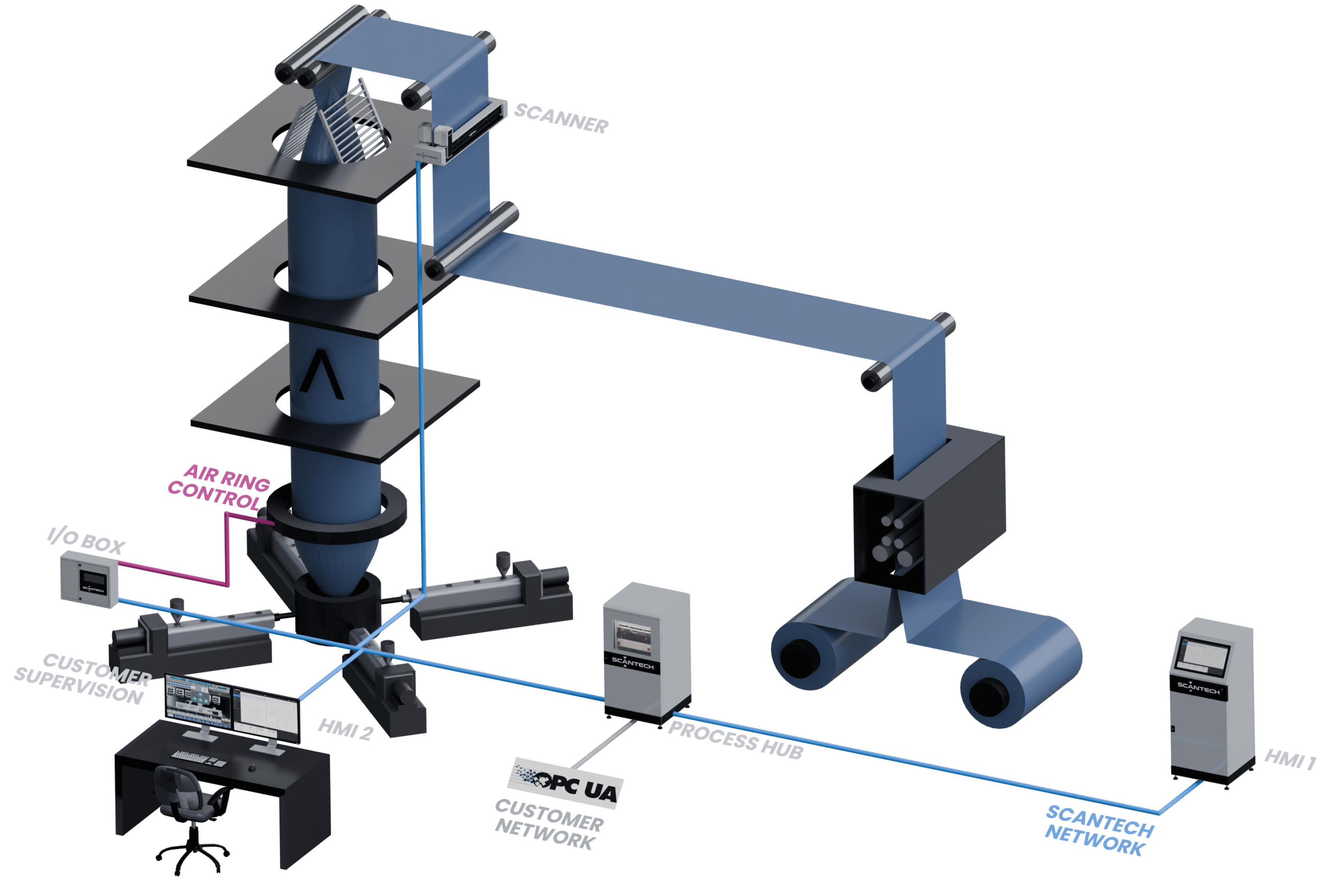

vertical web pass line

horizontal web pass line

The blown film process is being used for more and more high quality and advanced films whereas historically it was employed typically for basic, lower quality commodity films.

This progress has been enabled by the development of better-quality processing equipment and polymers.

Industrial gauging has also developed so where lines used to be run with no gauging or at best with slow gauges mounted on the bubble above the frost line today extrusion companies are investing in faster and more accurate measurement systems which are mounted on the lay-flat.

Scantech has developed specialised and sophisticated algorithms that allow for its widely acclaimed x-ray thickness measurement gauges to be mounted on an O-frame scanner to measure the film at the lay-flat. The algorithms allow for the deconvolution of the double layer so that profile can be accurately and stably mapped back to the die or air ring.

The advantage this solution brings is in the high accuracy measurement of the Scantech x-ray and the fact that the accurate mapped profile is available within a few scans meaning control actions can be made quickly (within a couple of minutes). This ultimately allows the film producer to make better quality films whilst significantly reducing scrap and out of spec film.