February 21, 2023

Anode thickness measurement is a critical process in the production of lithium-ion batteries. The anode is one of the two electrodes in a lithium-ion battery, and its thickness plays a key role in determining the battery’s performance. Accurately measuring the anode thickness during production is important to ensure that the battery meets the required specifications and performs optimally.

Importance of Anode Thickness Measurement

The thickness of the anode in a lithium-ion battery is an important parameter that affects the battery’s performance. Anode thickness affects the battery’s capacity, power, and cycle life. If the anode is too thin, the battery may not have enough capacity, while if it is too thick, the battery may have reduced power and cycle life. Therefore, it is important to measure the anode thickness accurately to ensure that the battery meets the required specifications.

Measurement Techniques

There are several techniques used to measure the anode thickness during battery production. Some of these techniques include:

-

Optical Microscopy: This technique uses a microscope to view the anode’s cross-section and determine its thickness.

-

Laser Scanning Confocal Microscopy: This technique uses a laser to scan the anode’s surface and create a 3D image, which can be used to determine the anode’s thickness.

-

X-Ray Fluorescence: This technique uses X-rays to measure the anode’s thickness by analyzing the amount of radiation absorbed by the anode.

-

Eddy Current: This technique uses an electromagnetic field to measure the anode’s thickness by analyzing the eddy current generated by the field.

Benefits of Anode Thickness Measurement

-

Quality Control: Accurately measuring the anode thickness during production ensures that the battery meets the required specifications, which ensures its quality.

-

Process Control: Measuring the anode thickness allows manufacturers to adjust the production process to optimize the battery’s performance.

-

Cost Savings: Anode thickness measurement can help manufacturers identify and correct production issues early, which can help reduce waste and save costs.

Conclusion

Anode thickness measurement is a critical process in the production of lithium-ion batteries. Accurately measuring the anode thickness ensures that the battery meets the required specifications and performs optimally. There are several techniques used to measure the anode thickness during production, including optical microscopy, laser scanning confocal microscopy, X-ray fluorescence, and eddy current. Anode thickness measurement provides several benefits, including quality control, process control, and cost savings.

Anode thickness measurement is a critical process in the production of lithium-ion batteries

“

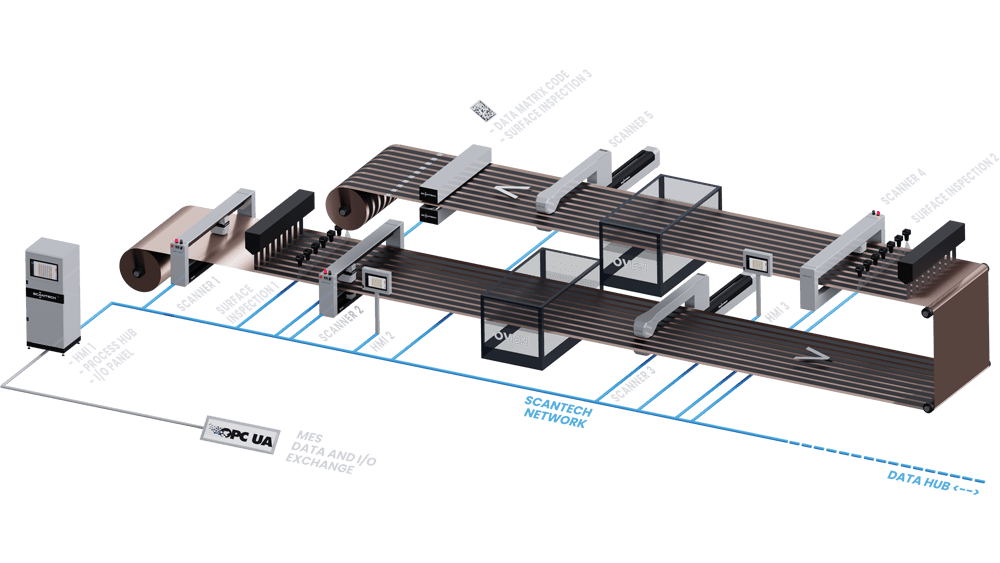

Discover our measurement solutions for the Anode manufacturing process.

Related Articles

Enhancing Aseptic Package Production

Optimize aseptic package production with Scantech’s advanced measurement solutions. Improve quality, productivity, and safety.

How to Calculate Density: Formulas, Examples, and Practical Tips

Density is a fundamental concept encountered in numerous fields of science and engineering, ranging from materials science.

Online Non-Contact Measurement: The Ideal Solution for Precise and Contact-Free Measurements

In a world where efficiency and precision are essential, Online Non-Contact Measurement has become a must-have solution for many industries.