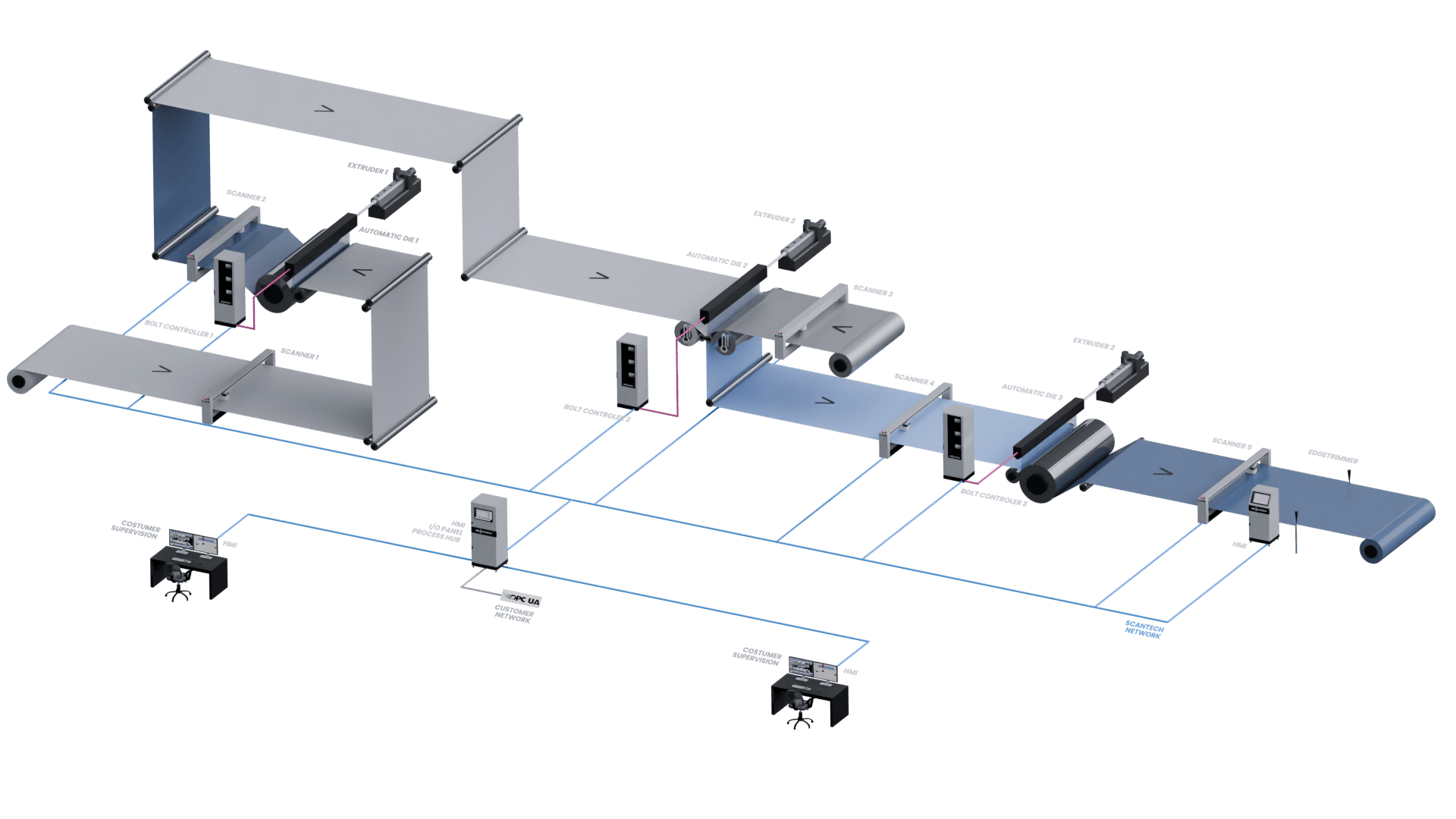

x-ray measurement solution FOR

ASEPTIC LIQUID PACKAGING

EXTRUSION COATING & LAMINATION LINES

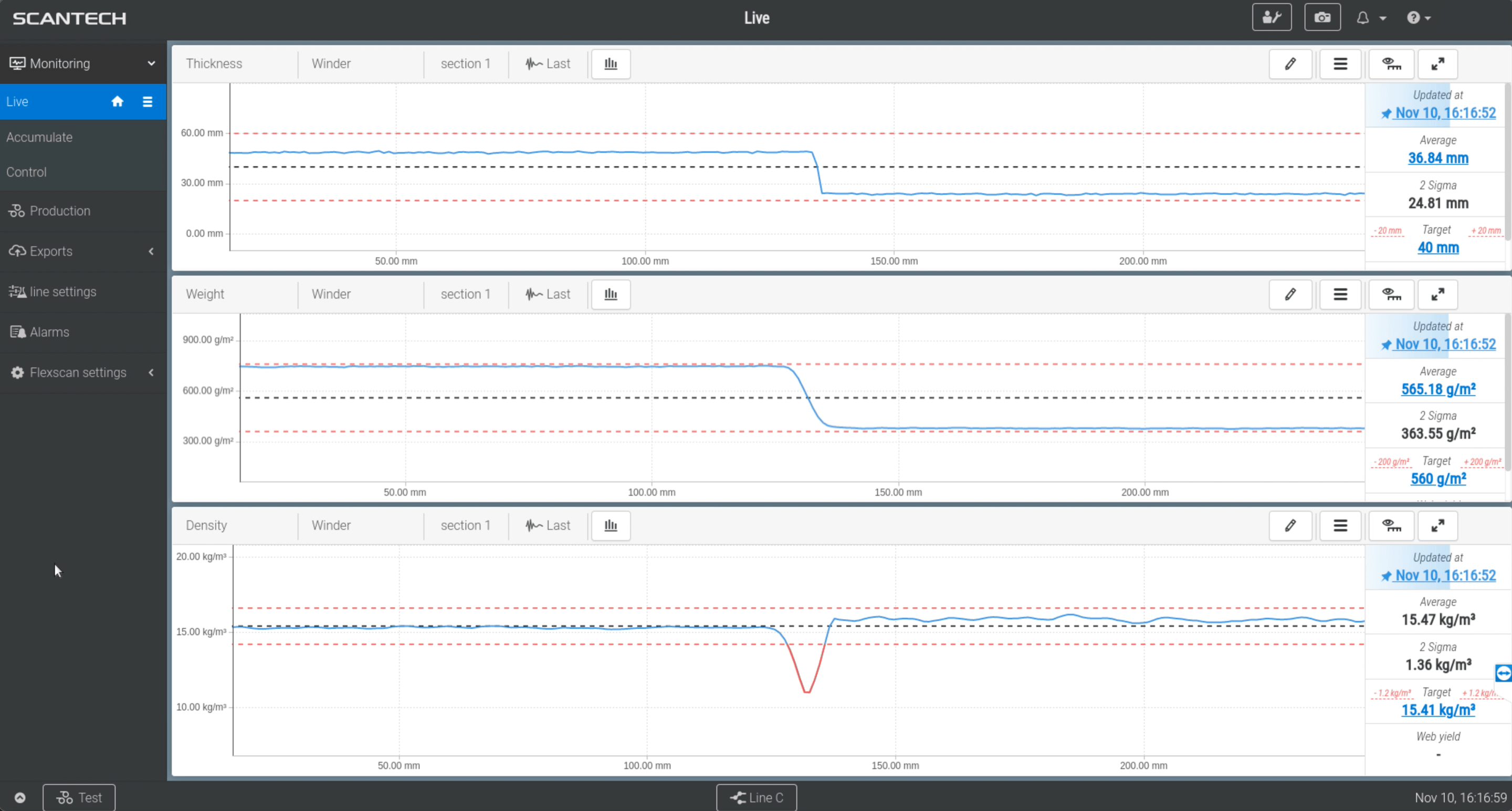

MEASUREMENTS

Coat-weight

Moisture

CONTROL

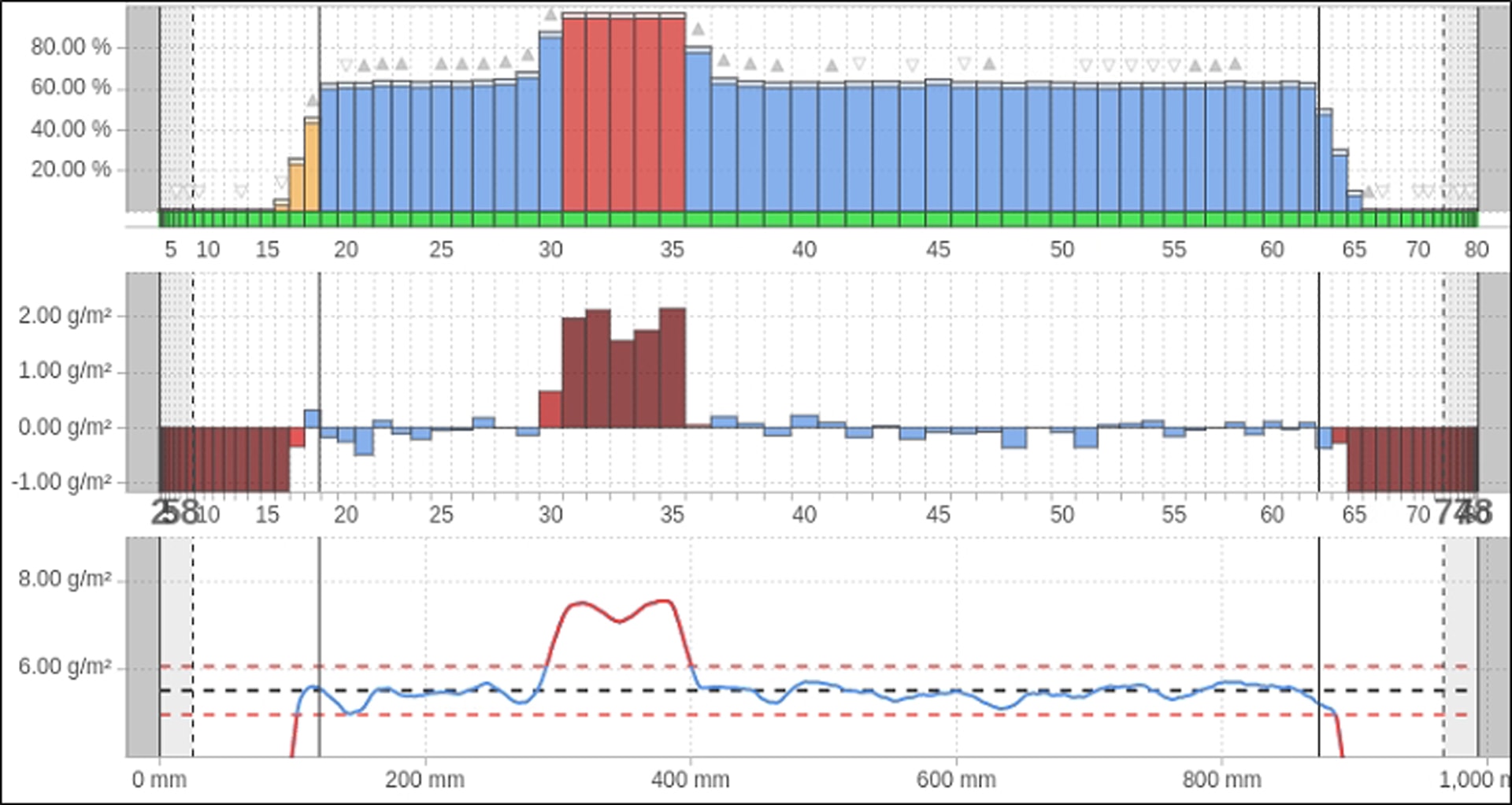

Bolt control

MD Control

Receive a baseline laboratory measurement report for your product

Learn more about

our technology

Contact our sales team

ULTRA LIGHT O FRAME

ULO3 SCANNER

X-RAY BASIS-WEIGHT MEASUREMENT

Precise die regulation

BOLT CONTROLLER

Power and temperature control

Our automatic mapping system provides updates to continuously address line drifts and extrusion errors.

This method works on all materials, widths, and line speeds.

> Control accuracy: 0.1% / 10 seconds

> Power: 300W max per bolt

FEATURES & BENEFITS

SYNCHRONIZED SCANNERS

Advanced Same Spot Measurement ensures accurate net coat-weight calculations by ensuring that the substrate and coat scanners traverse precisely the same trajectory on the web, even as line speed varies.

This synchronization eliminates sensitivity to point-to-point variations and formation in the substrate material.

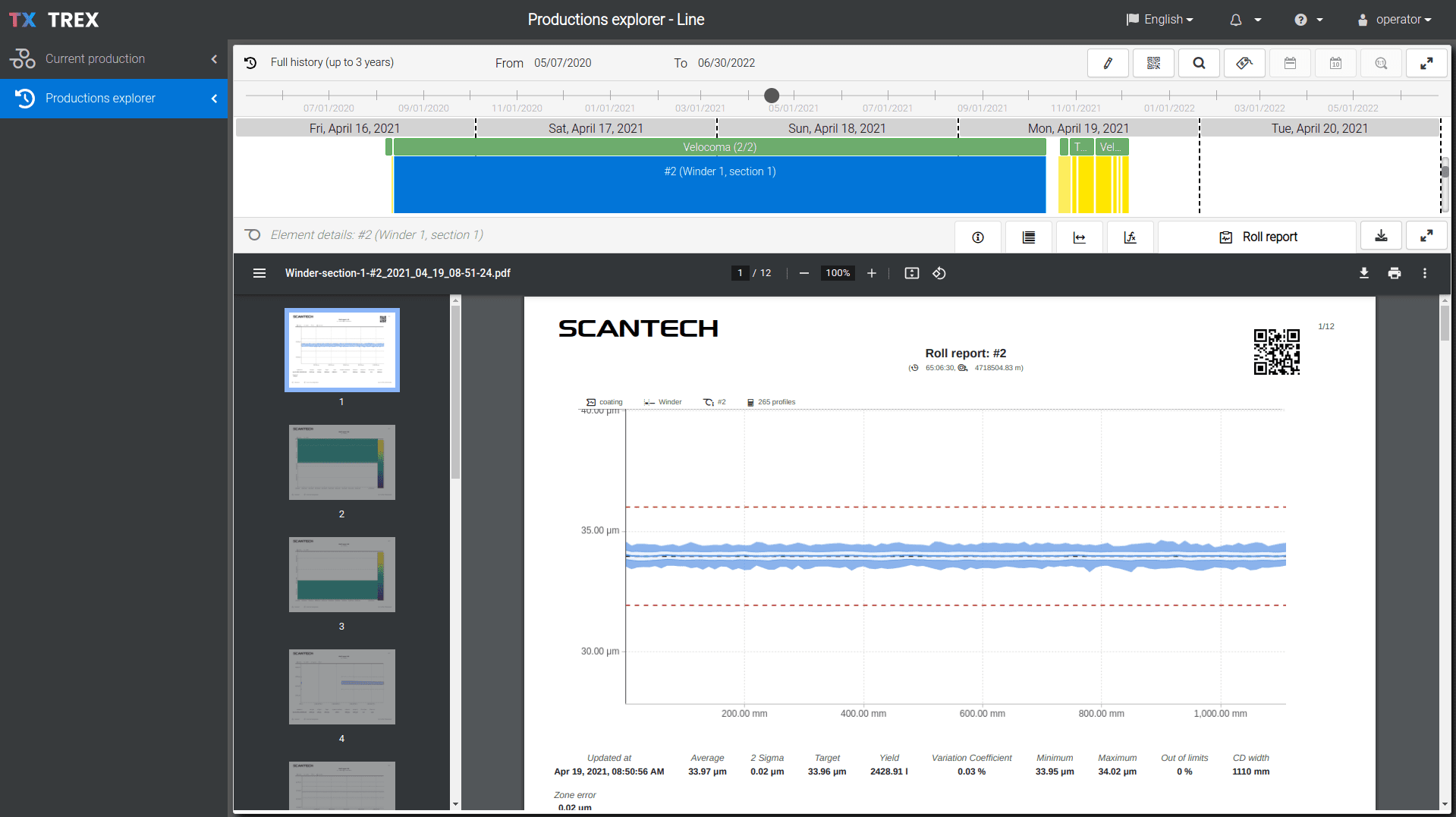

The TREX application is dedicated to browsing past and current production reports. Our unique tagging system allows archived reports to be retrieved, sorted, categorized, and collated.

Gather all the reports for a given customer during the last few years, or find all the reports for productions that use a given recipe.

Customize tags to fit your needs and the possibilities are virtually infinite!

Receive a baseline laboratory measurement report for your product

Learn more about

our technology