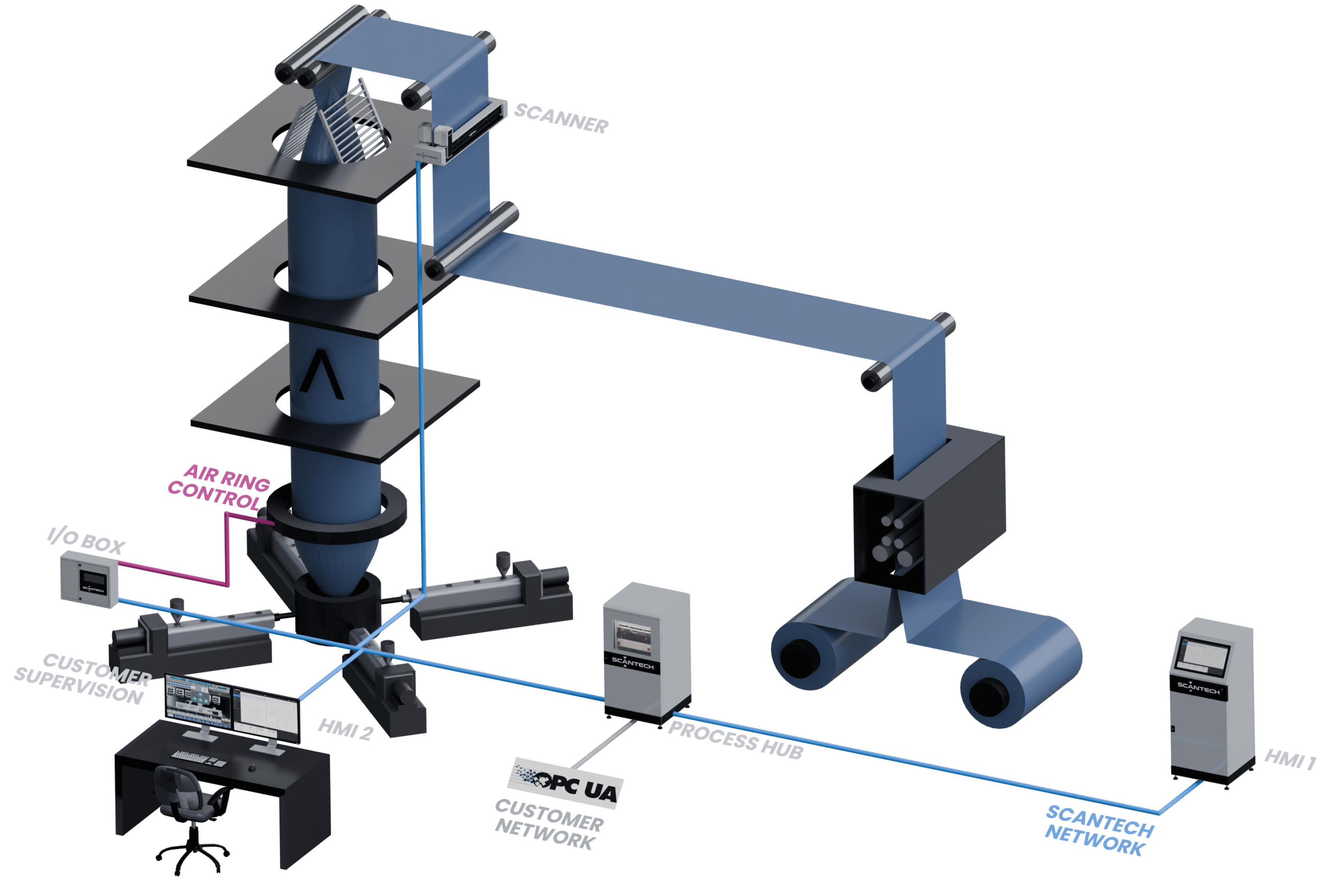

measurement & control solution FOR

BLOWN FILM

Faster and more accurate measurements resulting in more effective and quicker control leading to better film quality and reduced scrap

MEASUREMENTS

X-RAY

Thickness

Filler:

CaCo3 I TiO2 I BaSo4

CONTROL

Accurate

Mapping to air-ring or die

Fast

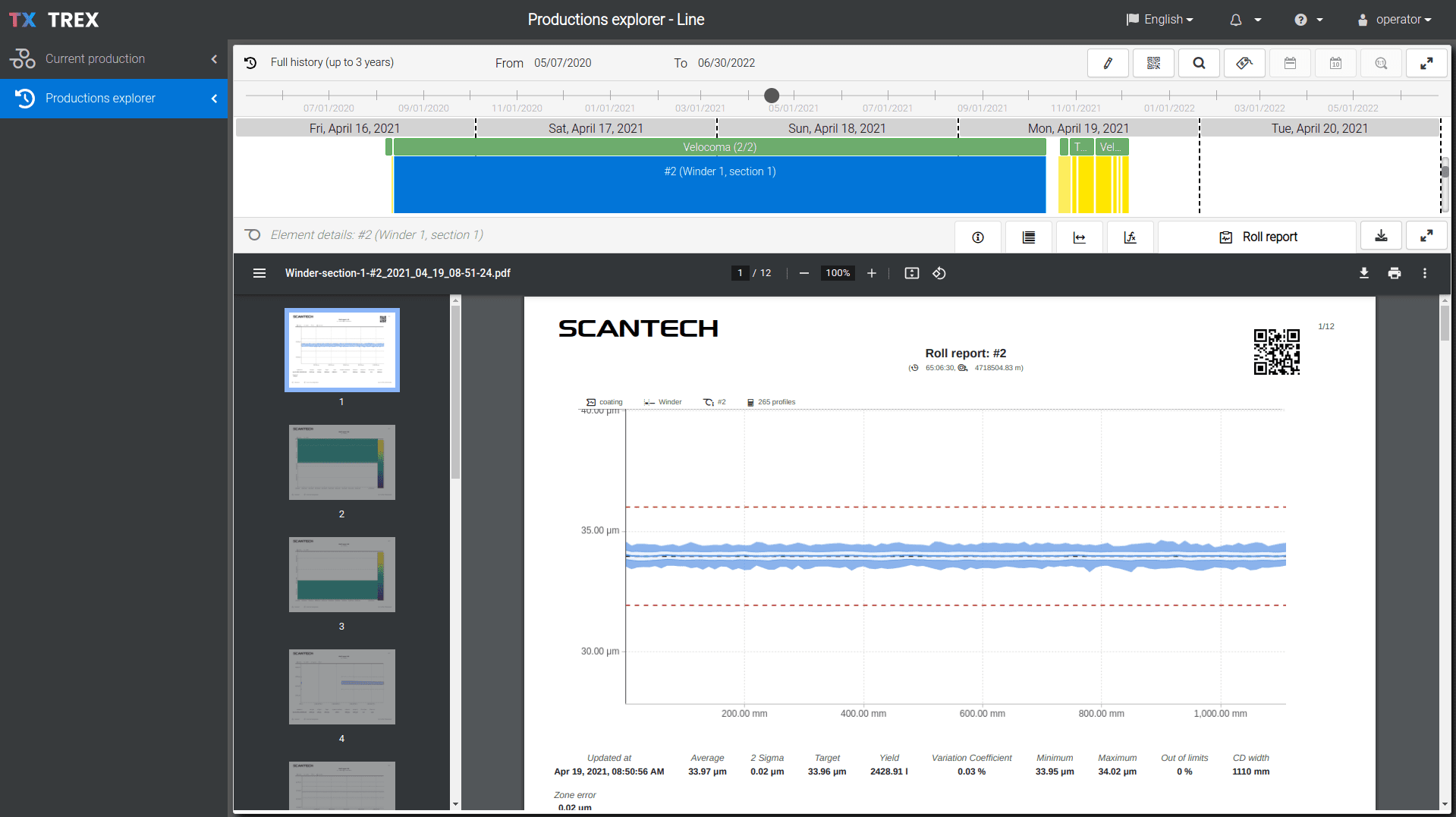

INDIVIDUAL WINDER REPORTS

Individual Polar Color Maps

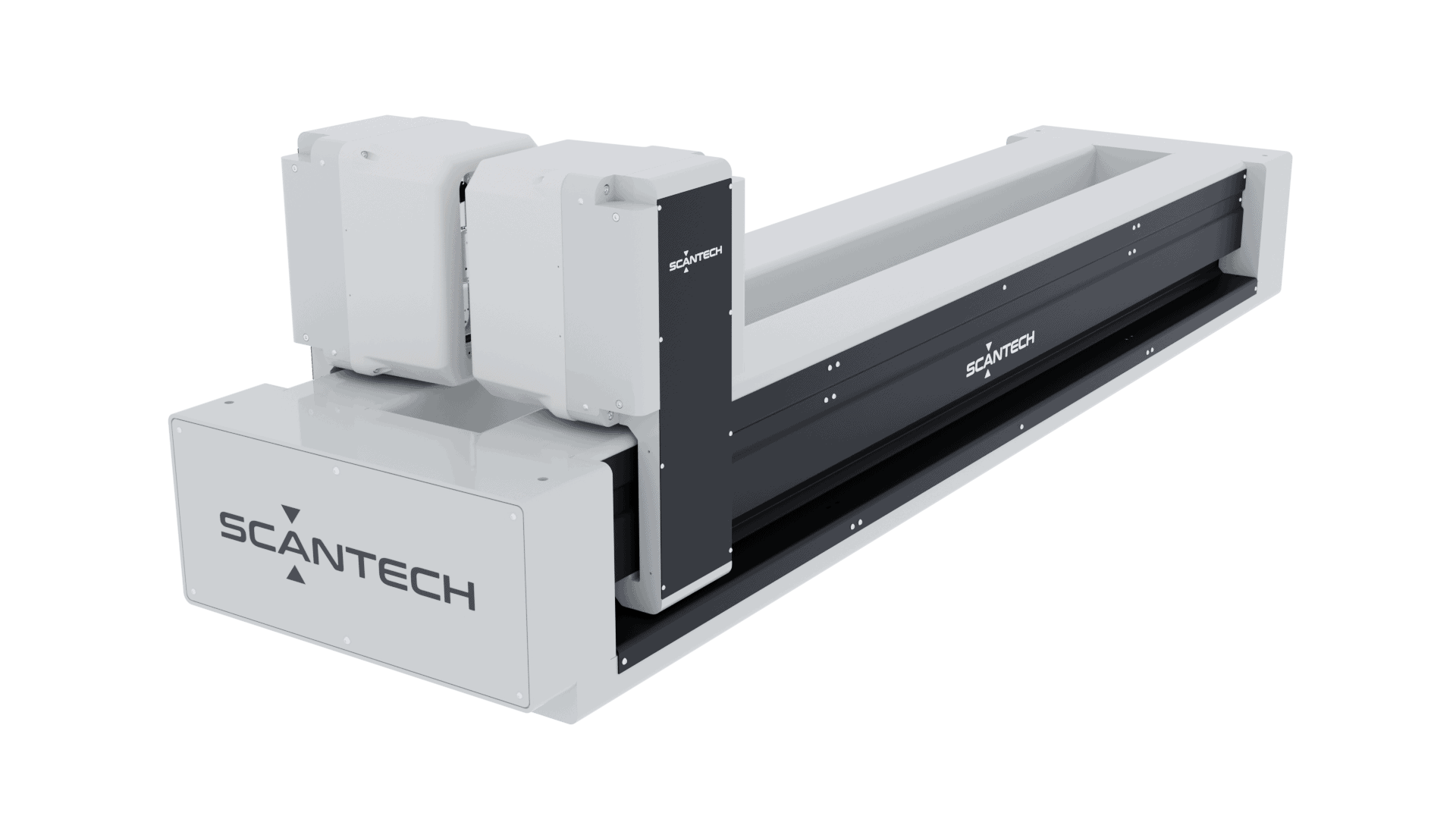

EXTREMELY COMPACT DESIGN

LH3 SCANNERS

X-RAY SENSOR

- Enables Easy Installation, closer to the collapsing frame, so providing for quicker control actions

- Proven high speed, high accuracy, high-fidelity measurement technology

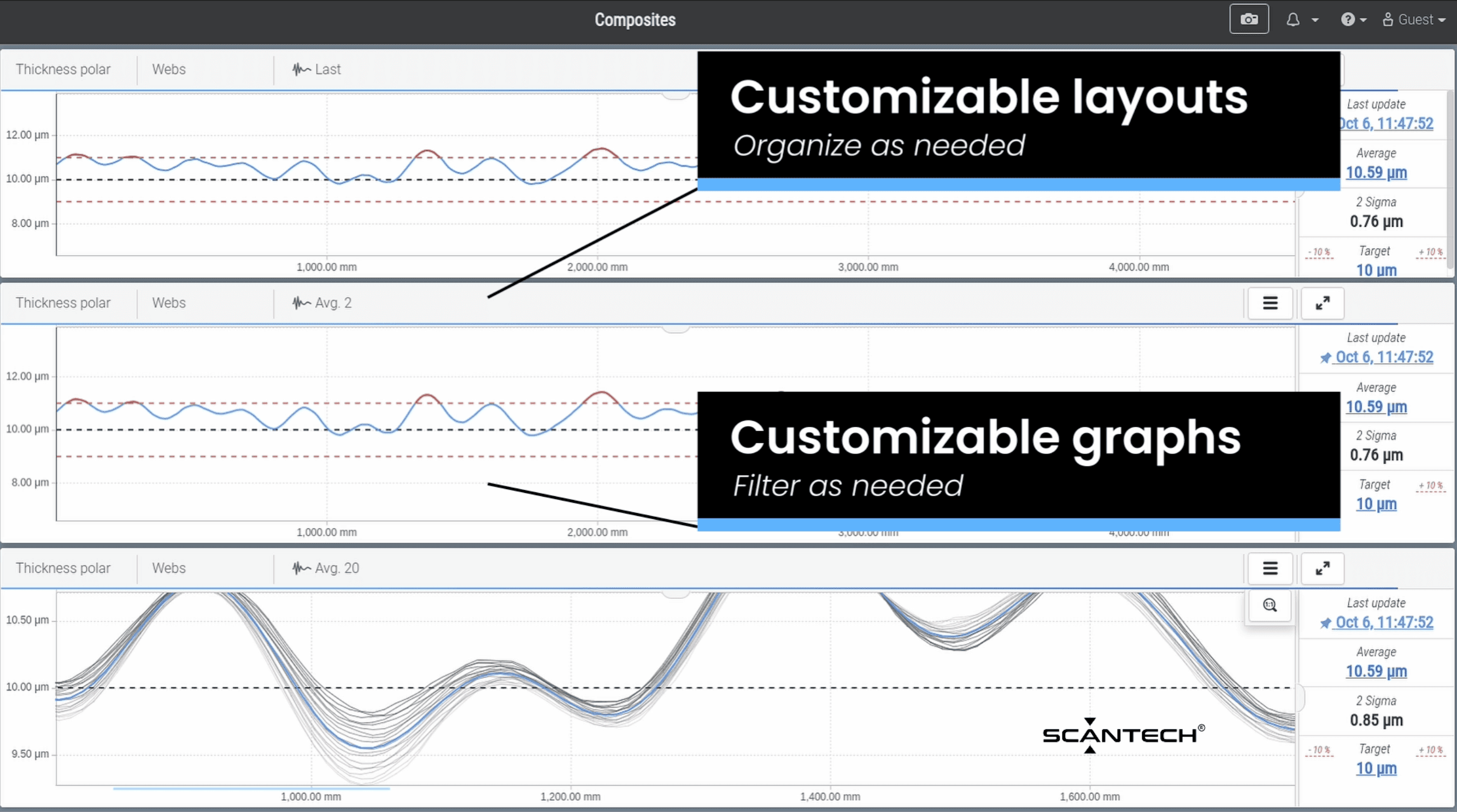

Interactive graphical representations of polar profile on Blown Film Extrusion.

The TREX application is dedicated to browsing past and current production reports. Our unique tagging system allows archived reports to be retrieved, sorted, categorized, and collated.

Gather all the reports for a given customer during the last few years, or find all the reports for productions that use a given recipe.

Customize tags to fit your needs and the possibilities are virtually infinite!

SCANTECH offers you a measurement and control solution to meet the process needs of blown film extrusion production lines for plastic films.

SCANTECH‘s measurement solution is faster and more accurate than standard measurement systems.

Faster, as there is 1 profile every 30 seconds, which reduces film production adjustment time.

More precise, because the measurement of the flat film allows a better precision on blown film extrusion.

A separate view and reports for the 2 production winders provide better quality monitoring.

A flat view and a polar view are possible simultaneously in the FLEXSCAN software.