SUPER HEAVY FRAME 3

VISUAL INSPECTION

Combines Multiple technologies

UP TO 15 METERS

360° VIEW

DATA SHEET

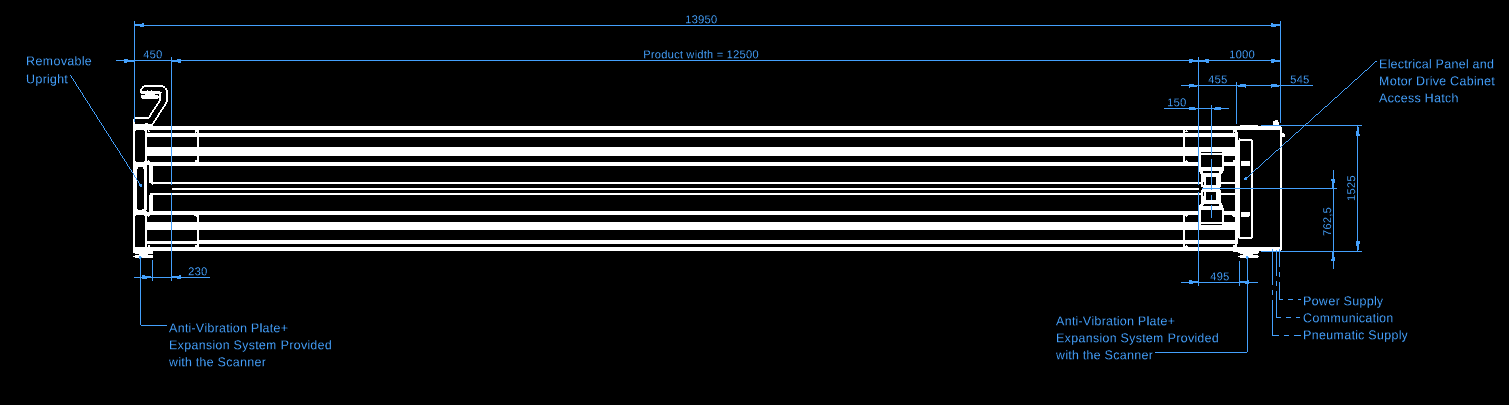

Example: 12500 mm model

DEPTH

450 mm

WIDTH

1778 mm <—> 14778 mm

HEIGHT

1600 mm

HATCH AVAILABLE

PRODUCT WIDTH

500 mm <—> 13500 mm

avaible product width

increments of 500 mm

RAL 7035

VISUAL INSPECTION

Combines classic measurements and visual inspection.

The defect detection cameras are locatedinside the frame’s beams.

OPTION

VISUAL INSPECTION

Optical imaging is the perfect solution for surface inspection. It can detect visual defects on both transparent and opaque materials. Combining dimensional and visual inspection measurements together allows you to easily quantify the performance of the complete production process.

EXAMPLES OF DETECTABLE DEFECTS

BURN DOTS

CONDENSATION

CONTAMINATION

DIRT

GELS

HOLES

INSECTS

OIL SPLASHES

OPACITY

SCRATCHES

STREAKS

WRINKLES

OPTIONS

For the combination of dimensional measurements and visual inspection.

In this case the cameras, located inside the frame beams.

Scanner Cooling System

Odometer

without or with bracket

with extended cable assembly

Pressurization For Frame

Electrical Panel & Heads

Expansion System Foot

3 Colors Indicators Lights

3 Buttons