February 2, 2023

Ceramic coatings play an essential role in the performance and safety of cathode electrodes in lithium-ion batteries. Measuring the thickness and uniformity of the ceramic coating is critical to ensure that the cathode electrodes are functioning as intended. The right measurement techniques can help to ensure the quality and consistency of the final product.

1. Optical Microscopy: This technique uses an optical microscope to visualize the ceramic coating and measure its thickness. It is a fast and non-destructive method, but it requires a skilled operator and can be affected by the surface roughness of the coating.

2. X-ray fluorescence (XRF) : this method is used to measure the composition and thickness of the ceramic coating, it works by irradiating the sample with X-rays and measuring the fluorescence X-rays emitted by the sample. It is a non-destructive method that can provide highly accurate results.

3. Atomic Force Microscopy (AFM) : this is a high-resolution imaging technique that uses a micro-scale cantilever to scan the surface of the ceramic coating in order to measure its topography and thickness. It provides detailed information about the surface structure and can be used for both imaging and measurement.

4. Spectroscopy: This technique uses light to measure the thickness and uniformity of the ceramic coating, it can analyze the chemical composition of the coating, providing information about the elemental content and their distribution.

5. Eddy Current Testing : this method uses the principle of electromagnetic induction to measure the thickness of the ceramic coating and detect potential defects by measuring variations in the coating’s electrical conductivity.

In conclusion, measuring the thickness and uniformity of ceramic coatings on cathode electrodes is essential to ensure the quality and performance of lithium-ion batteries. Techniques such as optical microscopy, X-ray fluorescence, Atomic Force Microscopy, spectroscopy and Eddy Current Testing can be used to accomplish this task, each with their own set of advantages and disadvantages. Choosing the right technique will depend on the specific requirements of the manufacturing process and the resources available. It is important to have accurate and reliable measurements for ceramic coatings to ensure the proper functioning and safety of the cathode electrodes.

In conclusion, measuring the thickness and uniformity of ceramic coatings on cathode electrodes is essential to ensure the quality and performance of lithium-ion batteries.

“

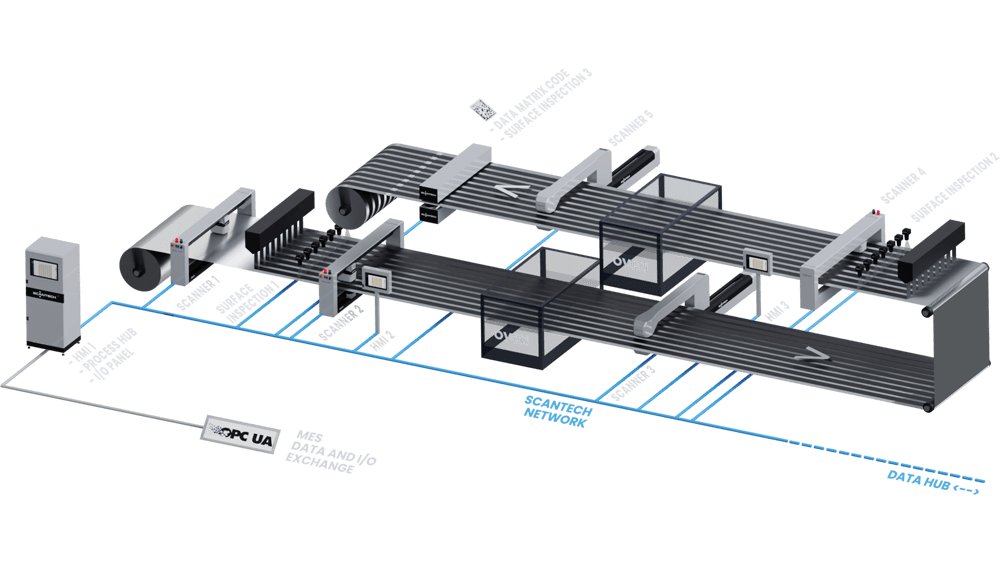

Discover our measurement solutions for the CATHODE COATINGS manufacturing process.

Related Articles

Enhancing Aseptic Package Production

Optimize aseptic package production with Scantech’s advanced measurement solutions. Improve quality, productivity, and safety.

How to Calculate Density: Formulas, Examples, and Practical Tips

Density is a fundamental concept encountered in numerous fields of science and engineering, ranging from materials science.

Online Non-Contact Measurement: The Ideal Solution for Precise and Contact-Free Measurements

In a world where efficiency and precision are essential, Online Non-Contact Measurement has become a must-have solution for many industries.